Mitchell Machine designs and builds custom machining equipment for high volume, special or large geometry parts, and special materials such as glass, semiconductor, and carbon fiber.

Automated loading and unloading systems allow the machines to be run automatically without additional operator costs.

Mitchell Machine has extensive experience in building robust machine tools for use in Optics machining and polishing, Semiconductor grinding and polishing, and carbon fiber manufacturing.

We supply various systems for parts deburring, flash removal, and polishing.

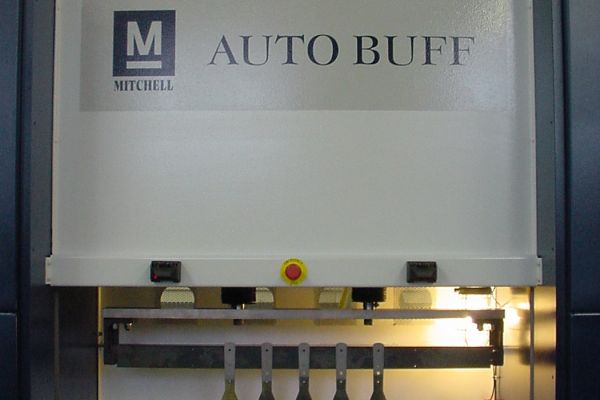

The Mitchell Machine AutoBuff is the answer for programmable, high speed, high volume finishing.

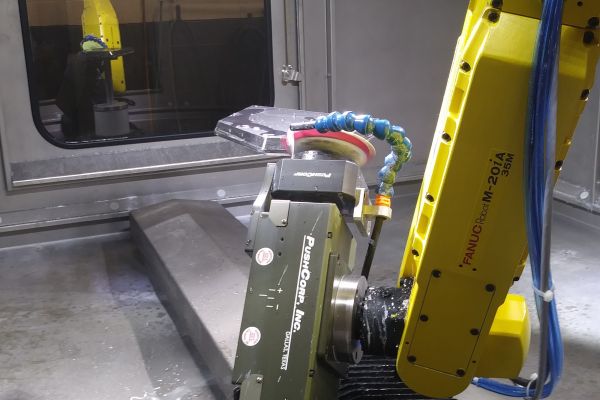

Robots perform many finishing operations traditionally done by hand with greater repeatability and no repetitive motion concerns.

Complex geometries and critical finishes can be achieved with Force compliant End of Arm Tooling.

Mitchell Machine forms strategic partnership with leading abrasive manufacturers to apply latest advances in abrasive technology.

“The foundation of Mitchell Machine’s process is the Machine Builder, operating in an environment where innovation and craftsmanship are highly regarded. These dedicated individuals, working in close cooperation with machine designers and highly skilled machinists, develop automated machinery that meets even the most exacting of our customer’s requirements.”