Our knowledge and experience with robotics systems help increase production consistency and process reliability which allows our customers to plan their production schedules to be more aggressive. Our highly experienced, dedicated robotic automation engineers design, manufacture and program turnkey robotic automation systems for a myriad of manufacturing applications including machine load/unload, part picking to assembly and inspection, material handling, part positioning, and multi-machine changeovers.

Leading manufacturers are introducing robotics into their production plants in ever increasing numbers for both material handling and processing tasks. High speed and repeatable motion control provide higher levels of quality and efficiency while reducing scrap costs due to defects, and repetitive motion injuries to employees. Menu based programming supports flexibility for product and process variables.

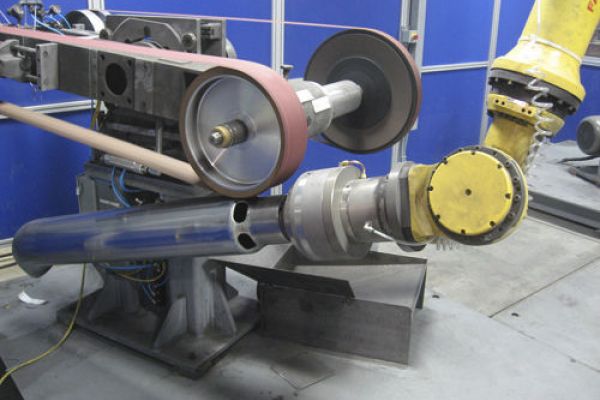

Cartesian, SCARA, 6-Axis and custom robotic systems by Mitchell Machine have be integrated into in adhesive dispensing, sheet handling, packaging, and assembly applications. We are factory certified integrators for Fanuc and Yamaha Robots and have experience integrating customer specified robots such as Denso, Mitsubishi, and IAI.

Robotic Automation Systems solutions are custom engineered, built and fully integrated into your application and process – from complete turnkey automation systems to specific robotic automation application needs and tooling.

“The foundation of Mitchell Machine’s process is the Machine Builder, operating in an environment where innovation and craftsmanship are highly regarded. These dedicated individuals, working in close cooperation with machine designers and highly skilled machinists, develop automated machinery that meets even the most exacting of our customer’s requirements.”