Mitchell Machine provides precision machining solutions for customers throughout New England. We have highly skilled engineers and technicians to meet your every machining need for the commercial, aerospace, medical device, semiconductor and defense industries.

Precision large part machining is one of our areas of expertise. There’s no need to sacrifice accuracy for size. With material handling capabilities in excess of 70,000 lbs, and machining capabilities to match, we can accommodate even the largest jobs.

Quality control is conducted throughout several points of the manufacturing process. A comprehensive range of inspections including incoming, in-process, final inspection, material and process certifications are available based on customer requirements.

Mitchell Machine introduced numerically controlled milling operations in the 1950’s and continues to be a leader today for precision machined parts at competitive prices. Experienced machinists and programmers deliver attention to detail and MADE IN USA quality on every order.

We specialize in smaller batch sizes, single, and prototype machined parts. Our capacities range from tool room work to large boring mill capacity in ferrous, non-ferrous, and plastic materials.

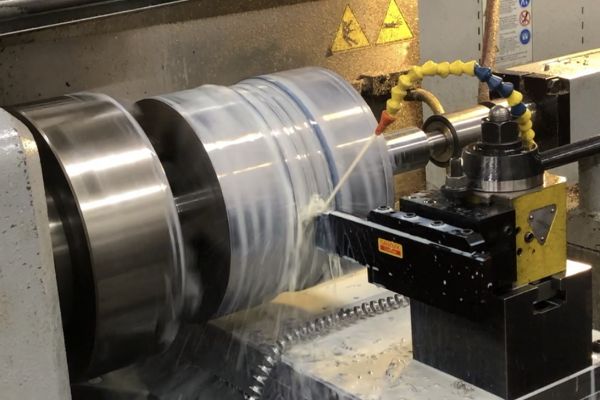

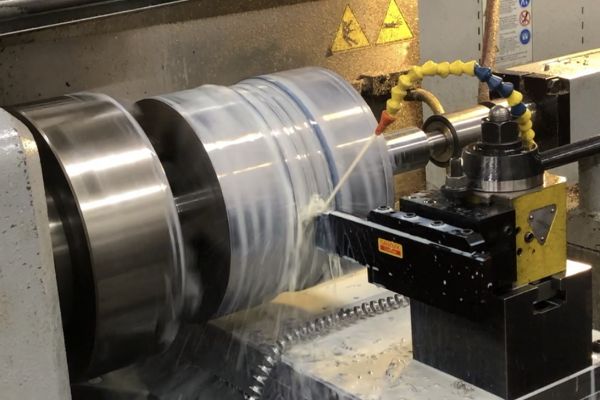

Mitchell Machine can tackle any turning project, large or small, no matter where you’re located. We use the latest cutting technology and highest quality standards to ensure you get the best quality product. Check out our gallery to get a better idea of what we do here at Mitchell Machine.

From simple drive shafts and tubular shapes, to complex bearing journals and rotating assemblies; close tolerance turning is a staple of Mitchell Machine’s manufacturing efforts. Our CNC turning equipment is capable of making prototype parts to small production runs. Talented machinists produce parts to yours exacting dimensions cost efficiently.

Mitchell Machine is capable of efficiently machining small to large parts. Our combination of state of the art large machining centers (144”x84”x72”) alongside our full service tool room makes Mitchell Machine your go to source for all you subcontract machining needs. With horizontal and vertical CNC machining centers featuring rotary tables and high speed spindles, complex parts can be machined in the most cost effective manner.

Mitchell Machine’s operators are experienced in a large array of materials including aluminums, stainless steels, and aerospace alloys. Our expertise is in large CNC milling but we also have extensive experience with smaller sizes and large productions runs. We also stock a huge variety of cutting tools which allows us to complete specialty or research and development jobs on a compressed delivery schedule. With an ongoing commitment to consistently improve our capabilities and processes, we are proud to ensure we can meet even the most demanding and specialized large milling requirements.

What are the Benefits of Boring?

Boring machines allow operators to achieve precise and demanding tolerances. Boring uses single-part cutting tools to enlarge pre-drilled holes in workpieces. Though similar to turning in many respects, boring is a challenging operation and requires a great deal of expertise to perform the process correctly.

Horizontal and vertical boring machines are defined by the orientation of their spindles. Horizontal boring mills keep workpieces stationary while tools turn to perform operations. Vertical boring mills utilize turning workpieces while the tools to remain stationary.

Horizontal boring offers more versatility because it accommodates much larger part sizes. There are a number of other benefits, including:

“The foundation of Mitchell Machine’s process is the Machine Builder, operating in an environment where innovation and craftsmanship are highly regarded. These dedicated individuals, working in close cooperation with machine designers and highly skilled machinists, develop automated machinery that meets even the most exacting of our customer’s requirements.”